PLC Training in DELHI , PLC Training in Delhi NCR

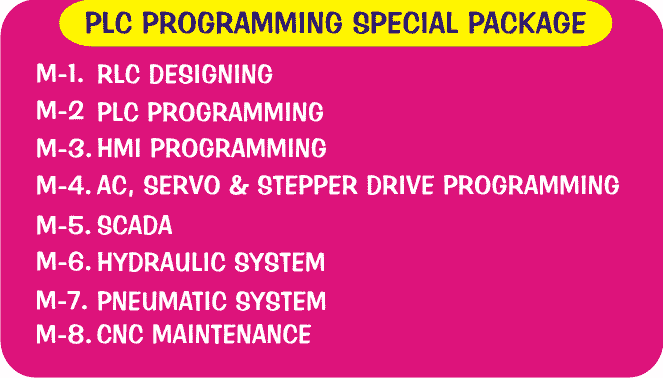

PLC TRAINING PROGRAMS IN DELHI NCR

|

For the advanced PLC training, Krishna Automation is a popular institute in Delhi NCR, where you get plc training with industry level practical at affordable cost by an expert faculty who have more than 12 years of experience in automation training.

Krishna Automation is a very old and genuine PLC training in Delhi NCR where you can do cost-effective advanced PLC Training Course, where there is a complete focus on Practical session on latest PLC station.

In Gurgaon (Delhi NCR), you get PLC training at the latest PLC Practical Station, from which you are always updated in latest technology in PLC course module. |

|

| |

|

| |

PLC TRAINING : Introduction :

The Programmable Logic Controller was developed in 1968 by the Engineers of General

Motors for replacing the complex relay logic control. |

Working Principle :

PLC is a microprocessor based solid state device.PLC works on the principle of Logic Gates. The input device may be pushbutton or limit s/w, relay contacts or timers etc. which send signal to the control elements and the o/p device may be motors, solenoid, relay coil, etc.

Inputs is given in the input image memory, CPU process it according to logic written in the memory and update the o/p in o/p image memory. PLCs control the components in the DCS and SCADA systems but they are primary components in smaller control configurations.

|

S No |

TOPIC |

RLC |

PLC |

1. |

Programme |

Made by Hardware |

Made by Software |

2. |

CPU Element

(Contactors,Timers and Counters) |

Physically used in RLC |

Replaced by Software |

3. |

Ladder Diagram Elements-

- Input

- Output

- Rung

|

Digital

Digital

Known as step |

Digital, high speed & Analog

Digital, high speed & Analog

Known as rung |

4. |

Digital Programme |

Is known as electrical control ckt. Diagram & made by steps. |

Is known as Ladder diagram & made by Rungs. |

5. |

Programme Scan |

RLC Scane the programme parallel |

PLC Scan the Programme sequencely in steps from top rung to bottom rung & scanning will be continue If PLC is in run mode & will be stop if PLC is in stop mode. One scan time is generally 10 to 20 ms. |

6. |

Use |

Digital Application |

Digital High Speed & Analog Application. |

7. |

Maintenance

- a – MTTR

b – MTBF

- Maintenance Time

- Running Cost

- Capital Cost

|

More

Less

More

More

Medians |

Less (if software is available)

More

Less

Less

More for small applications Less for big panels |

|

The new control system developed with following:

1) Simple programming.

2) Program change (editing) without system intervation (no internal rewiring) in a software.

SCADA Training

Supervisory Control And Data Acquisition refers to a centralized system and this system is composed of various subsystems like Remote Telemetry Units, Human Machine Interface, Programmable Logic Controller or PLC and Communications.

SCADA system is composed of 3 main elements.

PLC Training in Delhi NCR (Programming Languages & Logic Gates) :

The switching unit at input and output operate according to certain logic. The inputs can have only two values viz. 0 or 1, the basic elements may be electrical s/w, and transistors, relays, which have two states viz. 0 or 1. The languages for logic design are through the use of Boolean algebra. The basic logic function are ‘AND’, ‘OR’ and ‘NOT’.

PLC Programming Languages:

1) LADDER

2) FBD

3) STL

1) LADDER:

It is a language which represents the graphical view of electrical circuit. It is the combination of more than one ‘RUNGS’.

RUNGS:

When a coil is connected with series or parallel combination of digital inputs (NO/NC Contacts) elements is known as one ‘RUNG’. Combination of rungs known as Ladder diagram.

|

Programming Logic Control (PLC training in delhi NCR) system consist of

- • Inputs, Outputs

- • CPU

- • Power Supply

- • Memory for program & data storage

- • Power Supply

- • Operator Interface

- • Programming Device

KITC (Krishna Automation - Plc training in delhi ncr) is established to prepare young students/ aspirants for modern industrial need by their experience and knowledge. So that they can be productive from day one.

|

|

|

|

|

|

|

| |

|

|

PLC lab |

|

PLC class Schedule |

|

RLC Class Schedule |

|

H.M.I. Class Schedule |

|

AC drive Class schedule |

|

SCADA Class Schedule |

|

Hydraulic & Pneumetic

Class schedule |

|

CNC M/C Maintenance

Class Schedule |

|

|

| |

|

| |

| |

| |

|